ARTIFICIAL INTELLIGENCE – REDEFINE PRINTING

Welcome to AI srl, the company that is redefining the standards of the automotive glass industry through innovation, quality, and cutting-edge technology. We are proud to present our digital printing and quality control solutions, designed to meet the growing needs of the modern market.

AI is positioned as a leader in introducing digital printing to the automotive glass industry. With our advanced technologies, we overcome the limitations of traditional screen printing:

• High resolution and detail: Our digital printers guarantee sharp images and vivid colors, meeting the most demanding aesthetic requirements.

• Rapid Customization: Each piece of glass can be uniquely customized, without the need to redo masks or stencils, quickly adapting to design changes.

• Reduction of production changeover times: lthe rapid preparation of our solutions allows you to reduce production changeover times, responding promptly to market dynamics

• Operator’s Guide: provides precise guidance for solving problems, optimizing workflow.

• Consistent quality: ensures that every piece of glass meets the highest standards, reducing defects and waste.

Our mission is simple: to bring technological innovation to the automotive glass industry, ensuring high-quality products, extreme customization, and sustainability.

With a dedicated team of experts and an unstoppable passion for innovation, AI is the ideal partner for companies that want to excel in the modern market.

• Environmental sustainability: our technology optimizes ink use, reducing waste and environmental impact.

• Innovation in quality control:

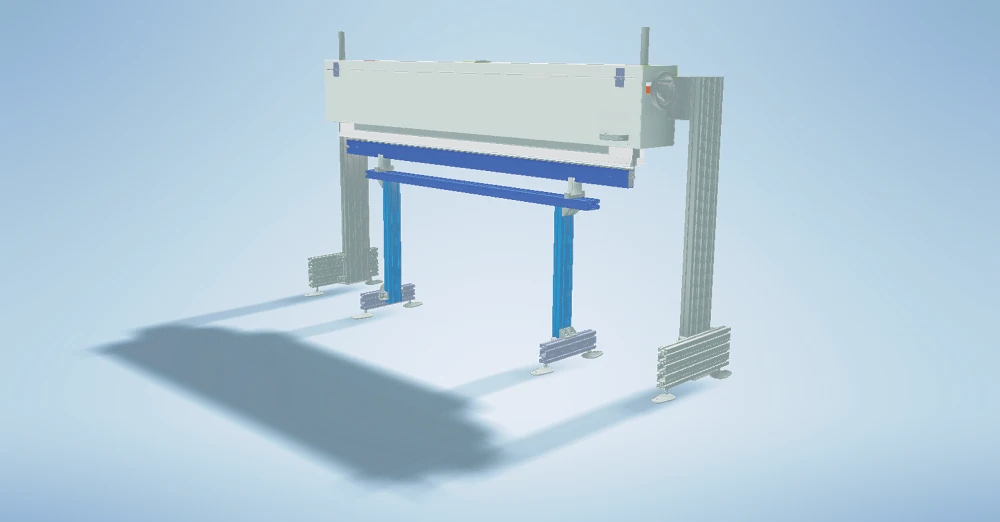

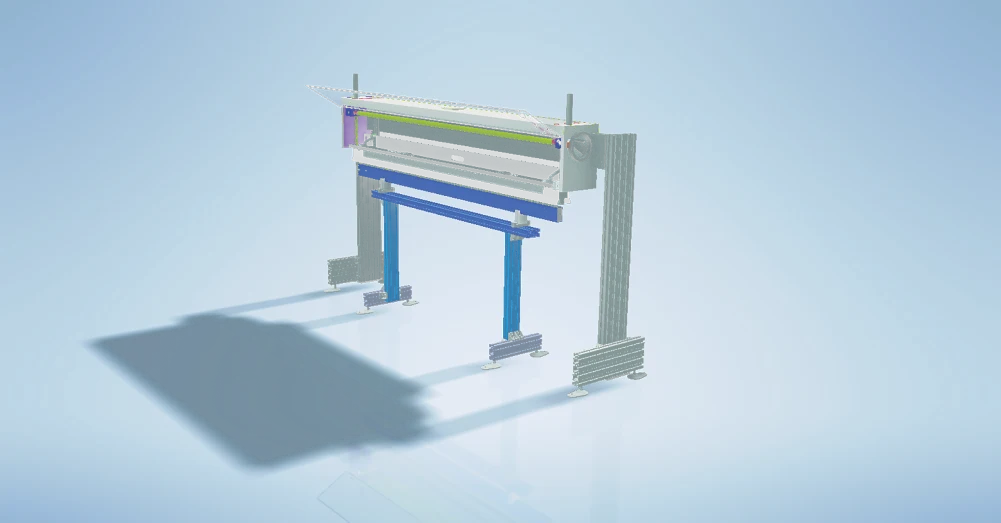

Our “Vision System”. To ensure superior quality in every piece of glass produced, AI has developed an advanced quality control system based on artificial vision.

Placed immediately after the digital printing process, this system offers:

• Instant Feedback: Instant detection of any defects in the print, with timely corrections. Automatic correction: The system makes changes in real time, improving production efficiency and reducing waste.

• Automatic correction: The system can make changes in real time, improving production efficiency and reducing waste.

• Experience and Expertise: Years of experience and deep knowledge of the sector allow us to offer tailor-made solutions for every need.

• Advanced Technology: We use the latest technological innovations to ensure exceptional results.

• Excellent customer support: a dedicated team is always available to provide support and personalized advice.

• Integrated solutions: we offer a complete package that includes both digital printing and quality control, for efficient and defect-free production.

In conclusion, AI is your ideal partner to revolutionize automotive glass production.

With our advanced digital printing and vision system for quality control, we help you reach new standards of excellence, responding to market needs quickly and efficiently.

Join us in the technological revolution and take your automotive glass production to the next level with AI!

The automotive glass sector is constantly evolving, and today more than ever, technology plays a crucial role in meeting the growing needs for customization, quality, and production efficiency.

Digital printing represents a fundamental turning point, but the real innovation comes when it is integrated with an advanced quality control system based on artificial vision.

Digital printing allows you to create highresolution, sharp and vivid graphics, overcoming the limitations of traditional screen printing. The advantages are many:

• High resolution and detail: flawless images that capture every detail.

• Quick customization: each piece of glass can be unique, without having to redo masks or stencils.

• Reduction of production changeover times: rapid preparation to respond quickly to market needs.

• Adaptability for every print run: economical for small and large productions.

• Environmental sustainability: reduction of ink waste and ecological impact.

• Innovation with quality control: The vision system. To ensure that each piece of glass is perfect, digital printing is supported by an advanced quality control system based on artificial vision. Positioned immediately after the digital printing process, this system offers immediate feedback in the event of errors, allowing for automatic correction and guiding the operator in resolving problems.

The advantages of the vision system:

• Instant feedback: : Instant detection of any defects in the print, allowing timely corrections.

• Automatic correction: The system can make changes in real time, improving production efficiency and reducing waste.

• Operator guidance: provides precise instructions to the operator to resolve any problems, optimising the workflow.

• Consistent quality: ensures that each piece of glass meets the high quality standards required by the automotive market.

• Cost reduction: minimizes defects and waste, reducing production costs.

The combination of digital printing with the vision system represents a perfect synergy for the automotive glass sector.

It not only allows to satisfy the aesthetic and functional needs of the modern market, but also to guarantee a constant and impeccable quality in every piece produced.

Digital printing, integrated with a quality control system based on machine vision, is redefining the standards of the automotive glass industry.

Companies that embrace this advanced technology can respond quickly to market demands, reduce production times, ensure superior quality, and improve operational efficiency.

It is a revolution that not only meets current needs but paves the way for a future of innovation and success.

ARTIFICIAL INTELLIGENCE – REDEFINE PRINTING

We are proud to present our digital printing and quality control solutions, designed to meet the growing needs of the modern market.

Copyright 2024 – ARTIFICIAL INTELLIGENCE – REDEFINE PRINTING

All Rights Reserved.